Introduction

PLC Shift applications work alongside a PLC. Seamless integration with a PLC is a core feature of PLC Shift. At run time, PLC Shift applications will synchronize tag values to the PLC. The following sections contain details on how the integration works and how it can be configured.

Synchronized Tags

Only tags that have the ‘Sync with PLC’ option selected are synchronized with the PLC at runtime. This mechanism allows for granular control over what values are made available in the PLC. If you have some configuration that you will never change at runtime, and don’t want to give the PLC the ability to write to those tags, then those configuration parameters should be left unpublished.

The same idea applies to status parameters. A single gas flow application has hundreds of tags to hold hourly and daily flow accumulations, but it’s unlikely that all these tags are required in the PLC.

Care must be taken when determining which tags to synchronize with the PLC. Each tag that is synchronized needs to be read from, or written to, the PLC. With too many synchronized tags, communications may take too long, causing problems with the whole system.

Synchronizing too many tags will create a bottleneck in the system when communicating with the PLC, especially with slower protocols like Modbus.

|

View ‘Controller DB Update Time’ status tags in the Device Status group to see how long PLC updates are taking

|

If the synchronized tags in an application change, the corresponding tags or objects in the controller must also be updated.

|

Parameter Types

A single tag is generated for control, status and user defined parameters.

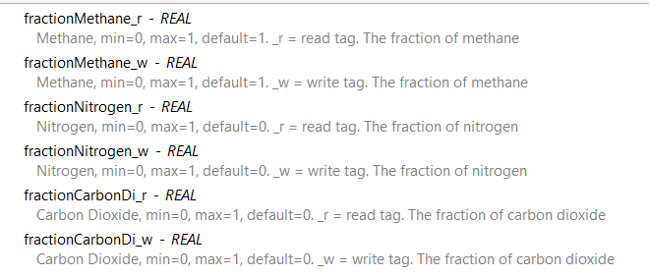

Configuration parameters are a special case, and each configuration parameter is mapped to two tags. The 'read' tag, which is post fixed with '_r', reflects the actual value of the tag in the application. The 'write' tag, which is post fixed with '_w' is written to by the PLC and allows the PLC to make changes to the application configuration at run time.

Configuration parameters are mapped to a 'read' tag and a 'write' tag.

|

Do not write to the 'read' tag in the PLC. This value is read only.

|

Configuration Parameters Read and Write Tags, Studio 5000

Device Level Configuration

Settings at the device level apply to all applications that the device owns.

Device Level Settings

When the value of ‘Enable Tag DB’ parameter is false at the device level, no attempt will be made to communicate with the PLC for all applications. Each application also has its own individual disable. These features are useful when a PLC is not available or when adding new applications to an existing configuration.

Application Level Configuration

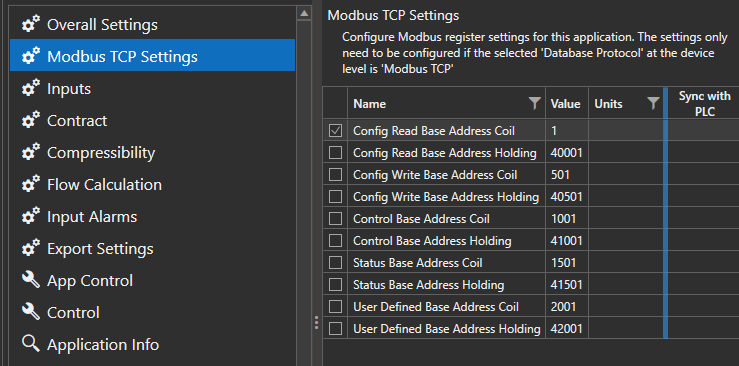

Settings at the application level apply only to the individual application. EtherNET/IP, OPC-UA and SCADAPack settings are in the 'Overall Settings' group. Modbus settings are in the 'Modbus TCP Settings' group.

Application Level Settings

Application Level Modbus Settings